Wa Tech => Aeration of liquids in the tank, basin or cannel - Wa Tech WLL => Electromechanical Works O&M

Single Equipment

Aeration Systems | |||

Aerator systems are used to transfer oxygen into liquids such as a lake, sewage or drinking water tank, etc. to start a process | |||

Surface Aerator | |||

Surface aerators are simple and effective systems that guarantee a constant, high level of oxygen in the liquid with low maintenance and electrical energy expenditure | |||

=> | Strong construction | => | Few items |

=> | Constang oxygen transfer | => | Low operation & maintenance costs |

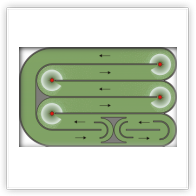

Fine-Bubble Aerators | |||

The ventilator system consists of many parts such as the blowers, control unit, piping, aerator grille and aerator. The sucked air is further heated and then fed to the system. | |||

=> | Many items | => | Temperature problems |

=> | Changing oxygen input | => | High operation & maintenance costs |

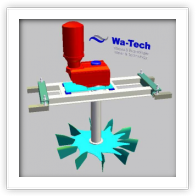

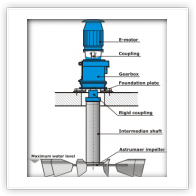

The Astrumaer top aerator is connected to a heavy duty gearbox. The Astrumaer top aerator is submerged into the water and rotates with a very low speed (40 - 90 rpm). The Astrumaer aerator is designed to ensure that the required splash action will start as close as possible to the centre of the aerator. This creates a very fine 360 degree circular splash pattern. The large surface area of the fine droplets and the long exposure to the air results in a very high oxygen transfer. Due to the very high and deep pumping action of the special designed blades the water will be taken up from the bottom of the basin creating a constantly and rapidly renewing of the water to be aerated with as result a higher oxygen mass transfer. Also the high turbulence at the water surface of the basin gives a further enhancement of the oxygen transfer.

The submerged horizontal plate creates a low and controlled axial load water pressure which ensures a stable and vibration free operation. This low axial load pressure also has been profen very effective for avoiding surging of the Astrumaer aerator.

The design of the Astrumaer aerator is such that clogging of the Astrumaer aerator will not occur under all conditions, even unscreened water.

The oxygen input factor of the aerator is up to 2.5 kg O2 / Kwh.

In contrast to the pressure aeration, the oxygen input factor of the Astrumaer surface aerator is constant over the entire service life of the aerator and dont need any service.

Due to the water surface movement and the resulting additional cooling, these aerators are ideal for warmer areas such as the MENA region.

The required cost of Operation & Maintenance of the Astrumaer top aerator is constantly low over the service life (only transmission oil change is required).